KWIK Composter, an innovative Bio-Mechanical Composter and Organic Waste Converter, powered by sustainable microorganism-based technology. It efficiently transforms organic waste, encompassing food scraps and biodegradable materials, into nitrogen-rich compost, reducing volume by nearly 80%.

Why use composters? What is the problem that they solve?

The KWIK Composter, designed to process over 25 kilograms of food waste, caters to various settings, including landfills, industrial canteens, residential communities, hotels, shopping malls, hospitals, and educational institutions in Chennai.

- A kitchen composter machine not only alleviates landfill pressures but also enhances soil quality, promoting healthier crop growth.

- State-of-the-art wet waste composting machines effectively mitigate harmful greenhouse gas emissions during the composting process.

- Incorporating organic waste shredding machines for city waste composting fosters urban job opportunities and elevates waste management practices.

- The establishment of waste compost plants leads to substantial savings on waste transport expenses.

- Waste compost plants open revenue generation avenues through the sale of city compost, fostering eco-friendly cycles.

- Embracing this approach aligns with Sustainable Development Goals, offering a lasting solution.

- Furthermore, it enables the accumulation of credits for certifications such as LEED, BREEAM, and Green Building, underscoring a commitment to sustainability. Chennai boasts some of the leading organic waste converter manufacturers.

Features of KWIK Composter

- Fully Automatic Organic Waste Composter, user-friendly

- Silent and odorless operation

- Proven and sustainable technology

- Potential for reduced segregation requirements

- Produces nitrogen-rich compost

- Low operating and maintenance costs

- Trusted by a broad client base

- Endorsed by MOEF and Environment Clearance Committee

- Approved by Chennai Municipal Corporation

KC Models

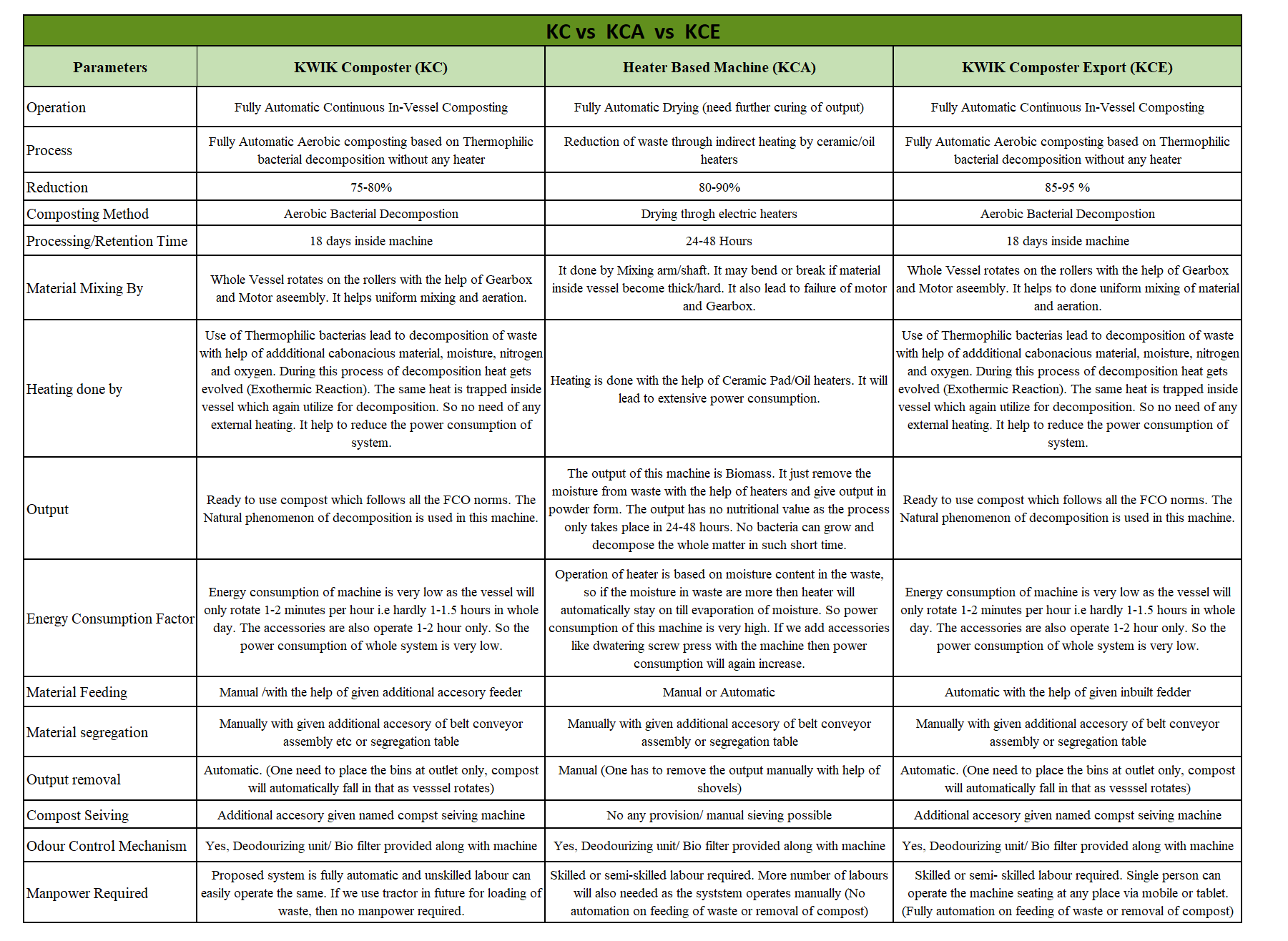

| KC MODELS | Dimensions | Connected load in HP | ||

| Length(mm) | width(mm) | Height(mm) | ||

| KC 2500 | 12,548.0 | 2,584.0 | 3,100.8 | 11.370 |

| KC 2000 | 10,548.0 | 2,584.0 | 3,100.8 | 11.370 |

| KC 1600 | 9,358.0 | 2,584.0 | 3,100.8 | 11.370 |

| KC 1200 | 9,358.0 | 2,340.0 | 2,808.0 | 7.640 |

| KC 1000 | 7,858.0 | 2,340.0 | 2,808.0 | 7.640 |

| KC 800 | 7,352.0 | 2,210.0 | 2,652.0 | 7.640 |

| KC 600 | 5,852.0 | 2,210.0 | 2,652.0 | 3.910 |

| KC 500 | 5,344.0 | 2,186.0 | 2,623.2 | 3.910 |

| KC 350/400 | 5,144.0 | 1,918.8 | 2,302.6 | 3.910 |

| KC 220 | 4,432.0 | 1,802.0 | 2,162.4 | 2.418 |

| KC 165 | 4,552.0 | 1,610.0 | 1,932.0 | 1.672 |

| KC 100 | 3,336.0 | 1,452.8 | 1,743.4 | 0.926 |

| KC50 | 2,732.0 | 1,202.0 | 1,442.4 | 0.926 |

| KC 30 | 2,732.0 | 937.0 | 1,124.4 | 0.926 |

* Dimensions may change as per the modification

* Segregation is required in heater based KWIK Composter Accelerators.

** Typical waste type is municipal waste, only rice, only apples, fish markets, meats.